Artisan

Text: Kosuke Ide

Photo: Keisuke Fukamizu

2022.08.12

In February 2012, at the largest handmade bicycle event in the world, NAHBS (North American Handmade Bicycle Show), awarded Japanese frame building factory, Cherubim, the event’s most coveted Best of Show award for it’s “Humming Bird” model. Soon, news rippled throughout the international cycling community as Shinichi Konno’s custom-order brand became known worldwide for its beautiful, avant-garde designs.

For professional cyclists in Japan, however, “Cherubim” is a venerable household name. The beginning of this legend dates back 50 years, back to a 1965 Japan where bicycle manufacturing basics and know-how were virtually nonexistent. It was during this time that Shinichi’s father and company founder, Hitoshi Konno, could be found in the yard outside his home in Setagaya, Tokyo, heating up racing frames and customizing them into competition bicycles. The company had started out as a “garage brand” in the most literal sense of the term, but in the short span of three years, a track bike made by Hitoshi in his tiny workshop had debuted at the 1968 Mexico Olympics and set a new Japan record. Almost overnight, the name Cherubim began synonymous with the highest level of Japanese frame making.

Absorbed in his craft, Hitoshi Konno continued to churn out novel ideas and revolutionary designs, leading industry insiders to refer to his passionate approach as “welding mania.” After Hitoshi retired, his son Shinichi took over the family business, and as one of Japan’s premier frame builders in his own right, established a madeto-order bicycle workshop in Machida, Tokyo. Though the new second-generation head of Cherubim was born in 1972, he was far from inexperienced, having been involved in crafting bicycles for almost 25 years. “From an early age, I was already participating in bike races. My father began teaching me right from day one.”

Cherubim bicycles are made to order. Based on a rider’s height and cycling needs, a builder will assemble the frame to exacting specifications. All frames are road bike frames made from chromoly steel, a special steel composed of chromium and molybdenum. In contrast to the more common frames made from carbon or alloy, individually hand-welded chromoly tube frames require a high level of skill to produce, and are becoming scarce even in European ateliers. Shinichi, however, is enamored with the special properties of chromoly, and continues to hone his craft. “If a bicycle is not optimized to a rider’s body and adjusted for his or her intended use, maximum performance cannot be achieved. Is this person strong, do they race, do they only cycle casually…when you put a frame together it is crucial to take these kinds of factors into consideration. And I believe there is no better material for bicycles than one of mankind’s oldest companions: steel. Even when it is specially processed, steel is still a highly general-purpose material, and can be adjusted to a very precise degree in order to control the nuances of how the bike rides. It is easy to repair and modify steel frames, meaning a steel frame can be with you for a lifetime. We have customers to this day who request tune-ups for frames that my father made many years ago.”

The lengths and angles of each part of the frame, the varying thicknesses at each point of the tube…all of these elements come together and affect the rider’s holistic cycling experience in very subtle ways. The crafting of such frames can only be performed by a trained artisan, and is not suitable for mass production.

“Take keirin riders for example – they can sense if a frame is even 1mm off from their optimized configuration. Having a highly skilled artisan craft each frame by hand- this is the only way to produce a frame to such minute specifications. Our company is founded not on the shallow idea of wanting to make things by hand for the sake of it, but rather the idea that, at this point in time, the only way to achieve the high standards we’ve set for our products is to make them by hand. Because we are craftsmen, it’s easy to have an image of us stubbornly sticking to our “old ways,” but we are actually quite progressive – if there are innovations in tube bonding techniques, we adopt them; if new, better machines are released, we use them; and we spend each day testing and retesting our methods to slowly improve the way we do things.”

Actively challenging new techniques and designs played an integral role in the story of the prize-winning “Hummingbird” model mentioned above. While staying true to his main line producing chromoly racing frames, Shinichi continues to push the creative envelope even further by designing experimental bicycles, just as his father Hitoshi had done before him.

“The thing to remember though, is that making something new is not easy. The basic “diamond frame” geometry of the bicycle has over 200 years of history, and stands upon the trials and errors of countless builders. Even if one succeeds in creating a novel design, it is likely that certain functionalities will be lacking. True innovation should not come so easily. I understand this well, but given my unique position as someone with the necessary skills and environment to make something truly new, I want to challenge myself in spite of the odds. So far I’ve yet to achieve that goal, but I believe there is great value in trying.(Reprinted from Subsequeznce vol. 5)

Artisan

Sol LeWitt: Open Structure

2026.02.16

Artisan

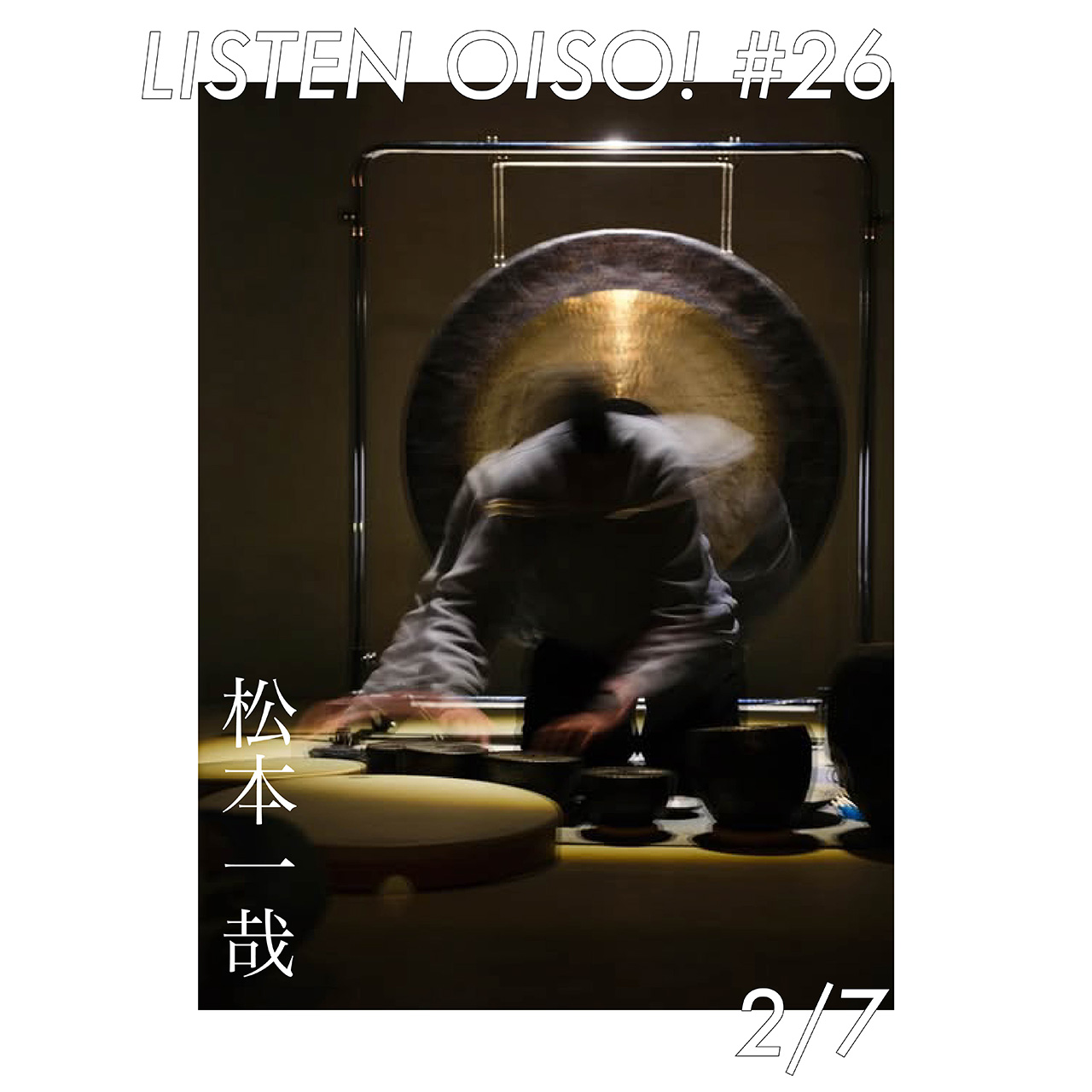

LISTEN OISO! #26

Daysuke Takaoka, Takashi Tsuda, and Kazuya Matsumoto

2026.01.26

Artisan

Lingering Memory / Michiko Van de Velde

2025.11.12

Artisan

Choreographies of the Everyday

2025.10.31

volume 08

2025-1st

Bilingual Japanese and English

260 × 372mm 148P

Release date: December 13, 2025