Almost All About

Almost All About Subsequence

vol.3 Printing and Ink

2024.09.03

Almost All About

vol.1: Binding

Subsequence

2022.08.16

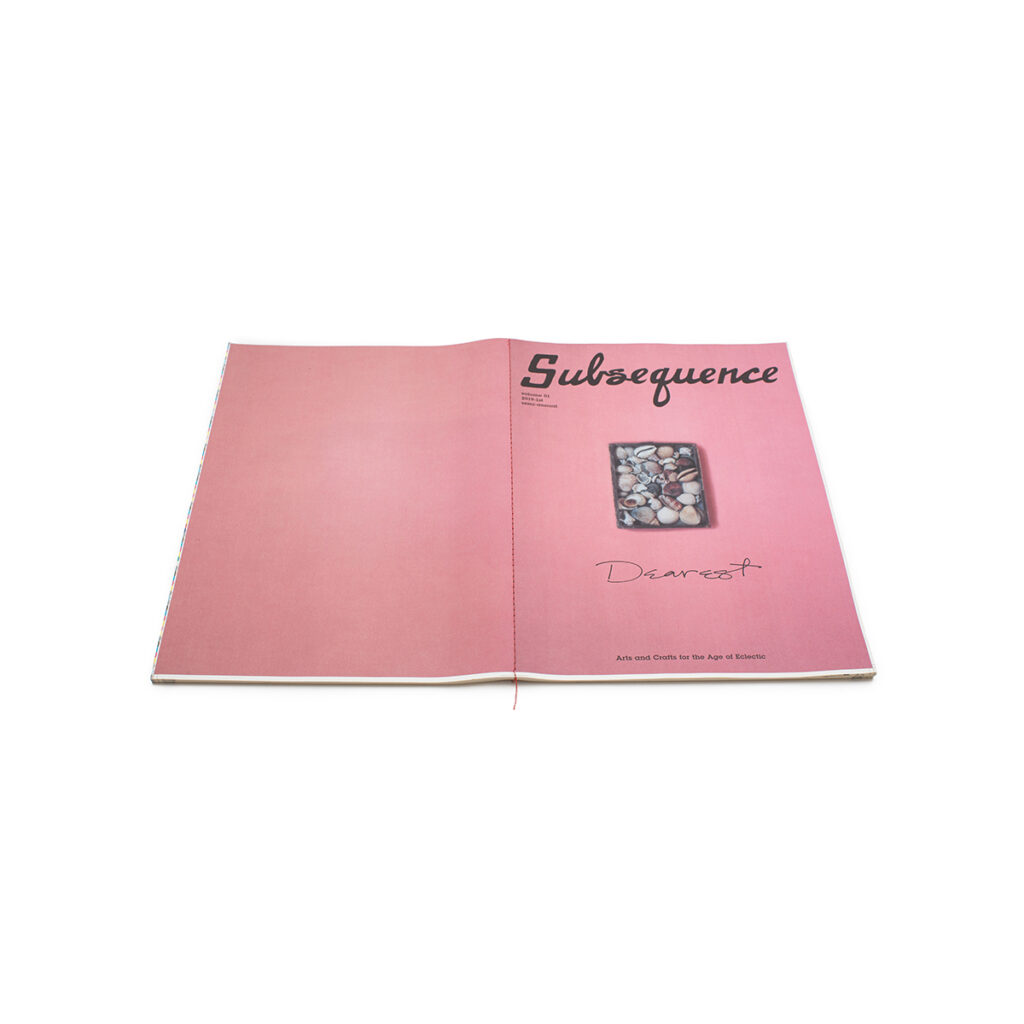

The production of Subsequence is an incredibly simple process. The printed pages are stacked and then bound together down the center using a sewing machine and thread in a process called center sewn binding. Due to the number of pages, however, a normal bookbinding sewing machine wouldn’t have the power to travel through all the paper, so we use an industrial sewing machine that is used for fabric. Our process is unlike usual book production and no part of it is automated with machinery. Each copy of Subsequence is carefully hand-bound by a craftsperson at the book binding specialists Shinohara Shiko.

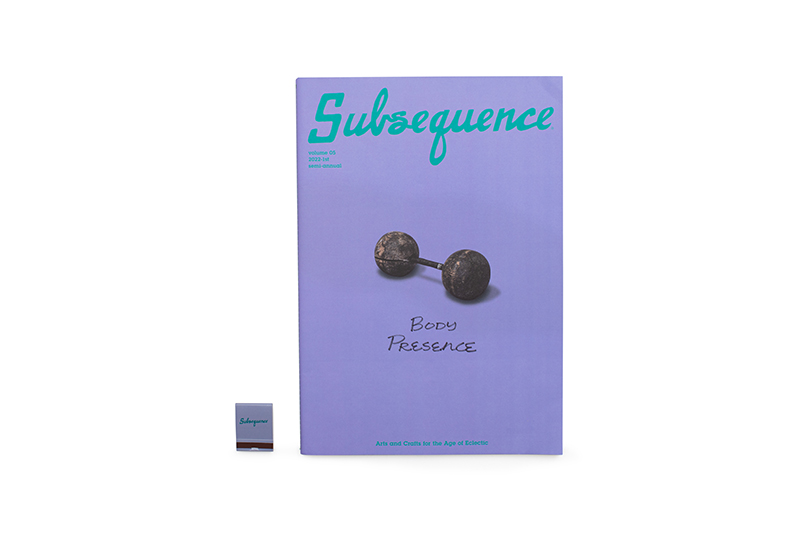

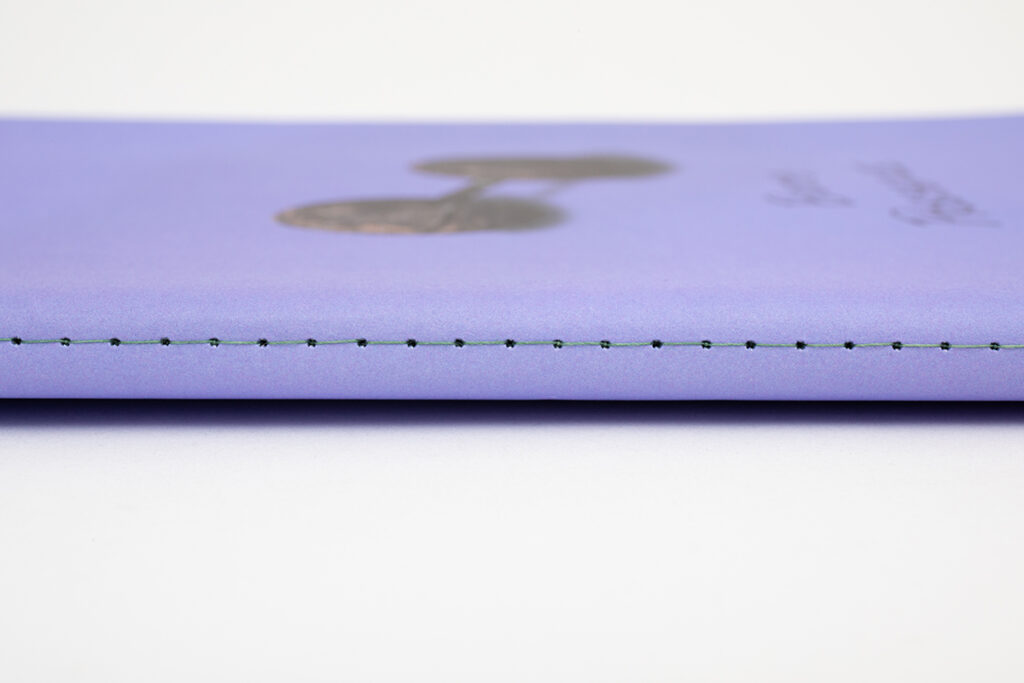

Subsequence is bound with naturally dyed thread the color of which is chosen to pair well with the cover of each issue. We used a fresh green-colored thread for vol.5 which was dyed with the leaves from kusa bamboo. As for the dyes for the thread used in other issues, vol.1 was carmine, vol.2 was walnut, vol.3 was chestnut, and vol.4 was gardenia.

Due to the size of Subsequence, the folding process is also done manually. The issue is folded in half, to give it the shape of a book, and handmade weights are placed upon it to secure the fold. Finally, after using a paper cutter to remove any excess, the magazine is complete. Although the process is simple as a whole, the number of steps requiring manual labor makes it feel less like making a magazine and more like a craft. We hope you’ll pick up a copy of Subsequence and enjoy the touch and scent that comes with physical media.

Almost All About

Almost All About Subsequence

vol.3 Printing and Ink

2024.09.03

Almost All About

Almost All About Subsequence

vol.2: The Magazine Format

2022.10.21